Advanced Mechanical Experience

Expertise and Professionalism in Mechanical Machining

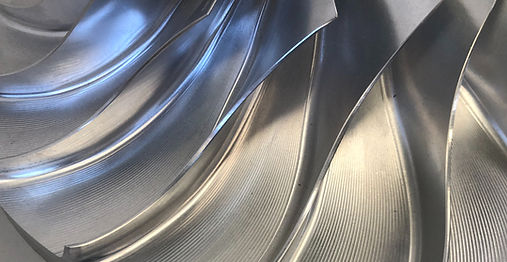

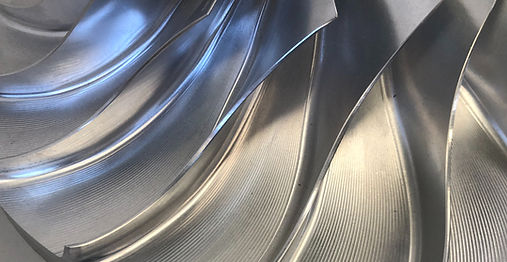

High-Precision Milling and Finishing

TecnoRossi – Top-Level Mechanical Solutions

High-Precision Milling for Motorsport and Biomedical Applications

At TecnoRossi, high-precision mechanical milling is more than a process — it's a passion driven by over 20 years of experience. We specialize in delivering complex, high-accuracy components essential to the motorsport and biomedical sectors, where precision and reliability are non-negotiable.

Our strength lies in combining deep technical expertise with state-of-the-art equipment. Every part we produce reflects our commitment to micron-level precision, efficiency, and technical excellence.

With a team of highly skilled professionals, TecnoRossi doesn't just meet the industry's toughest demands — we anticipate them. Whether it's a high-performance engine part or a critical biomedical component, we ensure impeccable results and total reliability.

Advanced Machining Technology

To ensure the highest levels of precision, reliability, and flexibility, TecnoRossi operates with a fleet of advanced machining centers and inspection systems, suitable for both prototyping and full-scale production, including unattended 24/7 operations.

CNC Milling Centers

-

DMG MORI DMU 70 EVO 5-axis continuous milling center with Heidenhain iTNC 530 CNC, Rotary table Ø700 mm High-pressure internal coolant for deep drilling 18,000 rpm electrospindle Equipped with EROWA Robot for unattended 24/7 production

-

GF Machining Solutions MIKRON HEM 500 U 5-axis continuous milling center with Heidenhain iTNC 530 CNC Rotary table Ø500 mm High-pressure internal coolant for deep drilling

-

Mikron HPM 1200 3-axis machining center with 20,000 rpm electrospindle (HSK interface)

High-pressure internal coolant Equipped with robotic system and 4 large pallets (800x600 mm Ideal for unattended 24/7 production -

Mikron VC1000 Machining center with Heidenhain TNC 430 CNC Equipped with 4th axis/dividing head

Quality Control & Inspection Equipment

-

Coord 3 BENCHMARK Automatic 3D Coordinate Measuring Machine (CMM) with interchangeable probe heads

-

Mitutoyo Linear Height 600 Height gauge with granite inspection table (1000x800 mm)

-

TRIMOS Height 600 Height gauge with granite inspection table (1000x800 mm)

-

ZOLLER Venturion 500 High-precision profile projector and tool presetting system

-

Additional metrology tools: Micrometers, gauges, plug gauges, calipers, and a full range of dimensional inspection instruments